en-us

- Home

- Solutions

- Applications

- Horizontal Applications

FOCUS

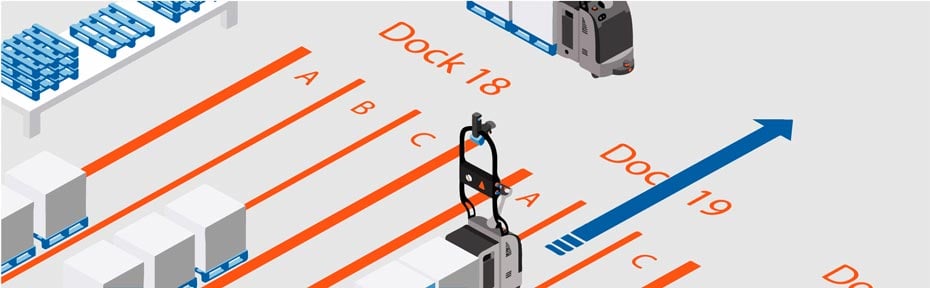

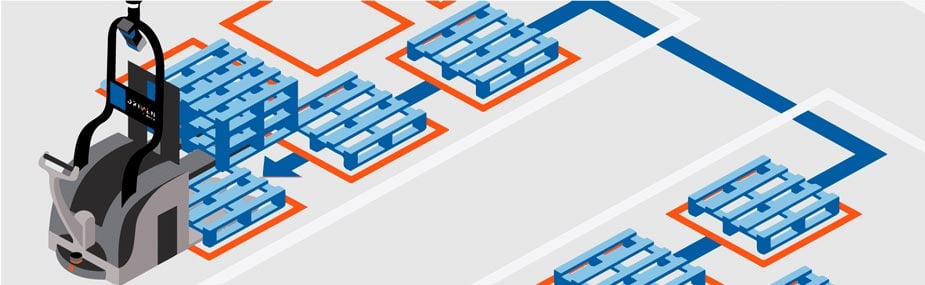

In warehouses or distribution centers, pallets are moved from inbound docking to storage area several times per day. Usually, an operator transports one or several pallets from receiving to end of aisles where vertical lift trucks can store them in high racking.

Robots Driven by BALYO can be used to replicate the path of manual drivers and complete long distance transports of pallets to end of aisles. Dedicated buffer areas can also be created throughout the warehouse where Driven by BALYO lift trucks will drop pallets that have to be stacked.

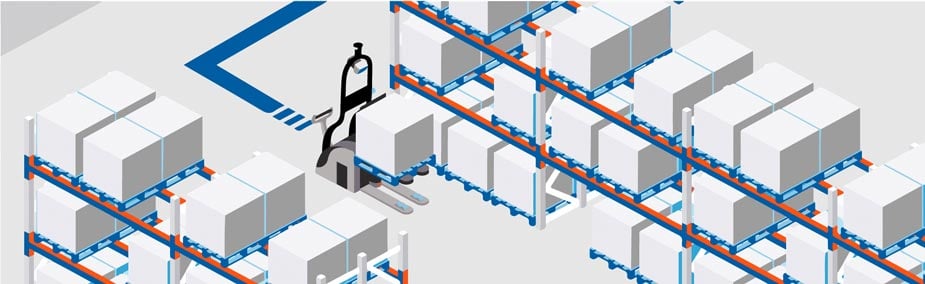

The BALYO robot range allows our customers to automate the full process: pallet transfer using robotic pallet trucks and racking storage using autonomous reach trucks or VNA.

SOLUTIONS

Intelligent Pallet Detection: This feature allows a robot to scan staging lanes using its safety laser, in order to detect and remove pallets from the zone. After a scan, if a pallet is detected, the information is sent by the robot to the BALYO Robot Manager that will trigger a pick mission. This robotic solution is fully autonomous and removes the need for a manual operator to trigger pallets removal.

FOCUS

In operations such as cross-docking or manufacturing, pallets that are delivered to an inbound staging area, need to be moved throughout the facility to quality control or staging areas. These pallets are usually manually scanned and delivered to a determined area.

Robots Driven by BALYO can increase efficiency in such operations using a barcode reader that can scan a pallet and determine the appropriate destination. This can be executed with or without the help of a WMS.

SOLUTIONS

Barcode Scanning: A BALYO robot can be equipped with a barcode scanner to read an identification plate on a load. If there is no WMS/ERP system, the BALYO will compare the barcode to a pre-populated database to determine the drop location.

Alternatively, you can also integrate the BALYO robot manager with a WMS system. In this case, the robot manager will receive instructions directly from the WMS/ERP which is taking over responsibility to assign pick and drop stations according to customer realtime needs.

If an identification issue occurs, BALYO can determine a default dropping scenario to ensure operational continuity.

FOCUS

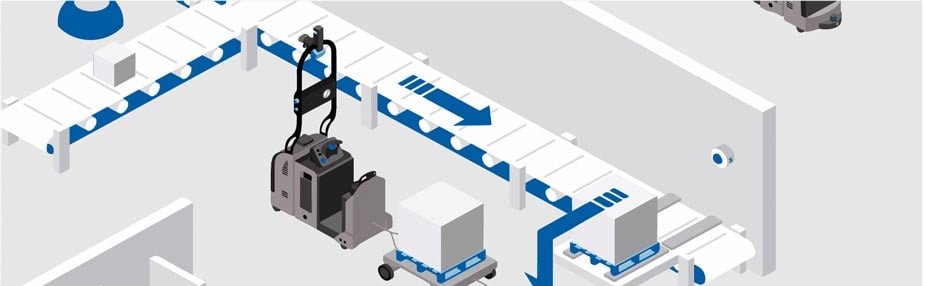

Large warehouses and distribution centers face the challenge of long distance pallet transfers. Such materials flows consist in transferring loads from inbound, long- or short-term storage, to an outbound area.

Manual operators are usually required to execute long distance travels and potentially have to go to the next movement empty handed.

With a Driven by BALYO robotic lift truck solution, you can avoid your operator painful and inefficient long distance operations. BALYO robots will take care of long horizontal movements between building or storage areas while your operators can work in a limited zone, being dedicated to added value tasks.

FOCUS

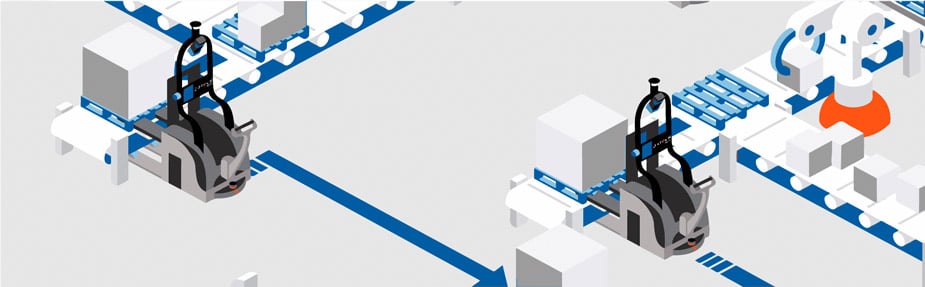

A typical application for manual operators is driving tugger trucks pulling carts with materials to be delivered in multiple locations in a production facility. The Driven by BALYO solution automates the tugger routes removing the need for manual operators to drive in loops all day.

The Driven by BALYO tugger can pull up to 7000 kg carts loaded with goods. This type of application implies a high level of human/robot interactions (cobotics) to manage trailers or loads. The tugger missions can be triggered through an interface with a WMS/ERP software or through a push button that operators can use to assign a pre configured task to a robot.

SOLUTIONS

Push Button Configuration: In any BALYO installation, missions are triggered by an event (pallet detection on conveyor, signal from palletizers…). If there is no WMS/ERP interface, triggers can be manually managed on the robot’s HMI, the Robot Manager screen or through robot features such as the intelligent pallet detection. Alternatively BALYO can offer a three button COMBOX where each button is assigned to a mission trigger, based on customer needs: raw materials supply, finished goods removal, pallet transfer, etc.

FOCUS

When the manufacturing process is done, finished products need to be transported to another location such as a storage area, pallet wrappers, quality control, packaging or outbound staging areas. All of these logistic flows can be managed by a robotic lift truck Driven by BALYO.

BALYO robots can interface with every equipments along the manufacturing and shipping processes. At industrial customers, our robots usually transport pallets from:

– Production lines to palletizer.

– Palletizer to wrapping machine.

– Wrapping machines to buffer or storage areas.

The end of production is now fully automated without requiring additional operators but focussing employees on manufacturing operations.

SOLUTIONS

Machine Interface: The Balyo Robot Manager can interface with machines via a COMBOX (communication module). The COMBOX will get a signal from a pallet detection sensor or the machine itself when a pallet is ready to be picked up. That signal will trigger a mission which will call for the next available robot to come pick up the pallet and drop it to the designated area.

FOCUS

During the manufacturing process, products have to be moved from a working cell to another. Usually managed by conveyor systems and/or manual lift trucks, it implies that production operators will be partly dedicated to handling tasks. Conveyors can automatically transport pallets but are complex to deploy and not scalable.

The Driven by BALYO robots are developed to manage tasks that do not generate value for the company. Keep your operations flexibility with a solution that adapts very easily to layout changes, thanks to a unique navigation technology.

Upgrading from manual to robotic handling will allow your workforce to be focused on manufacturing operations and bring activity growth opportunities.

SOLUTIONS

ERP Interfacing: Interfaced with your manufacturing infrastructures and your ERP software, the BALYO solution can now improve your daily operations. When a pallet is ready to be moved to another working cell, your ERP sends a message to our Robot Manager that calls a robot to proceed.

The development of this BALYO/ERP interface is made by our commissioning team in collaboration with your IT department.

FOCUS

Within a manufacturing cell, pallets transporting materials come in and need to be removed or stored once they have been used, which is not a priority task for production operators.

Robotic lift trucks have the best return on investment when they are continuously working.

A robot can be used to not only drop off material pallets but also to pick up and remove empty pallets from the production area. Managing this low added value task will save operators time and allow them to focus on the manufacturing operations. This type of robotized applications can result in a growth of activities with the same quantity of employees.

SOLUTIONS

Palletizers: The BALYO Robot Manager can interface with an equipment like a palletizer to trigger missions. BALYO can set up a system where a robot notifies a successful drop off of an empty pallet, so the palletizer can start its own work. The palletizer can also notifies that a pallet is ready to be picked up, then the robotic lift truck will manage.

Learn more about our products and technology, sign up to our newsletter!